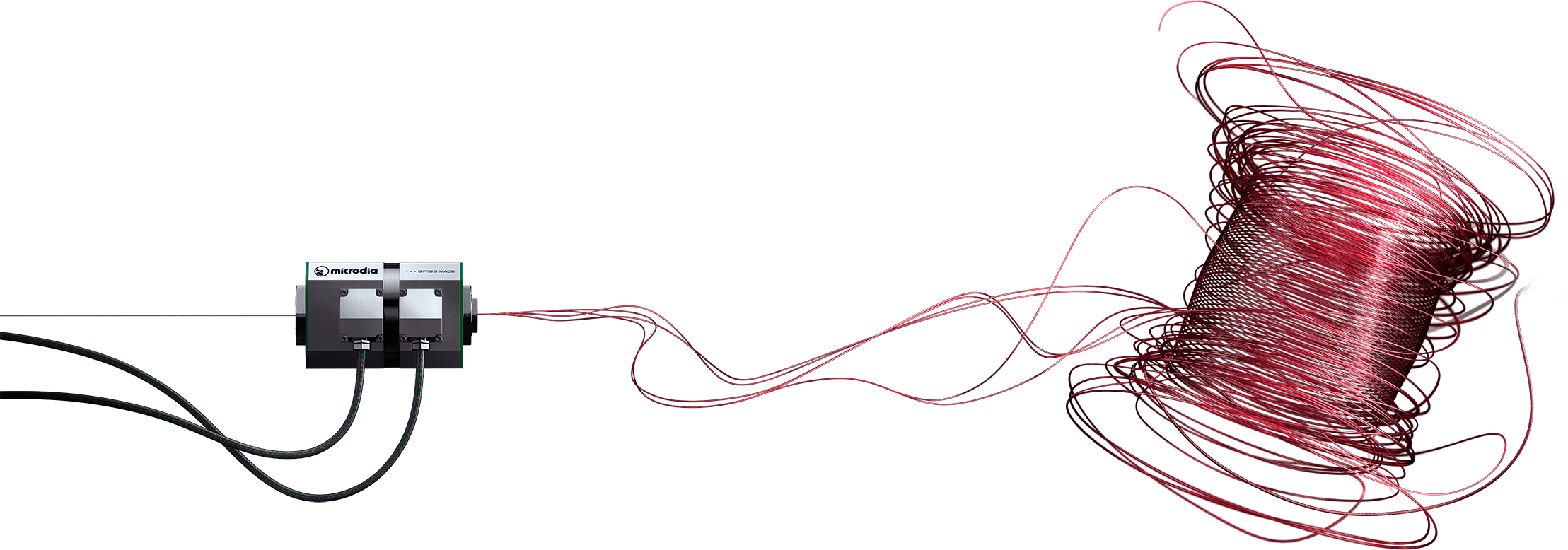

Cable

Specialities —

Fluomex 10 Mflex SLS

min conductor |

0.1 mm / 0.1 mm / 0.1 mm / 0.2 mm / 0.3 mm |

max conductor |

1.5 mm / 4 mm / 5 mm / 12 mm / 22 mm |

max over insulation |

|

max tube die diameter |

5 mm / 12 mm / 20 mm / 35 mm / 50 mm |

Insulation |

Small solid and stranded wires |

domain of use |

Mini coax FEP Special chemical applications Fuel lines Data cables Plenum cables HTW - High Technology Wire |

Compound |

Fluoro polymers PTFE / FEP / PFA |

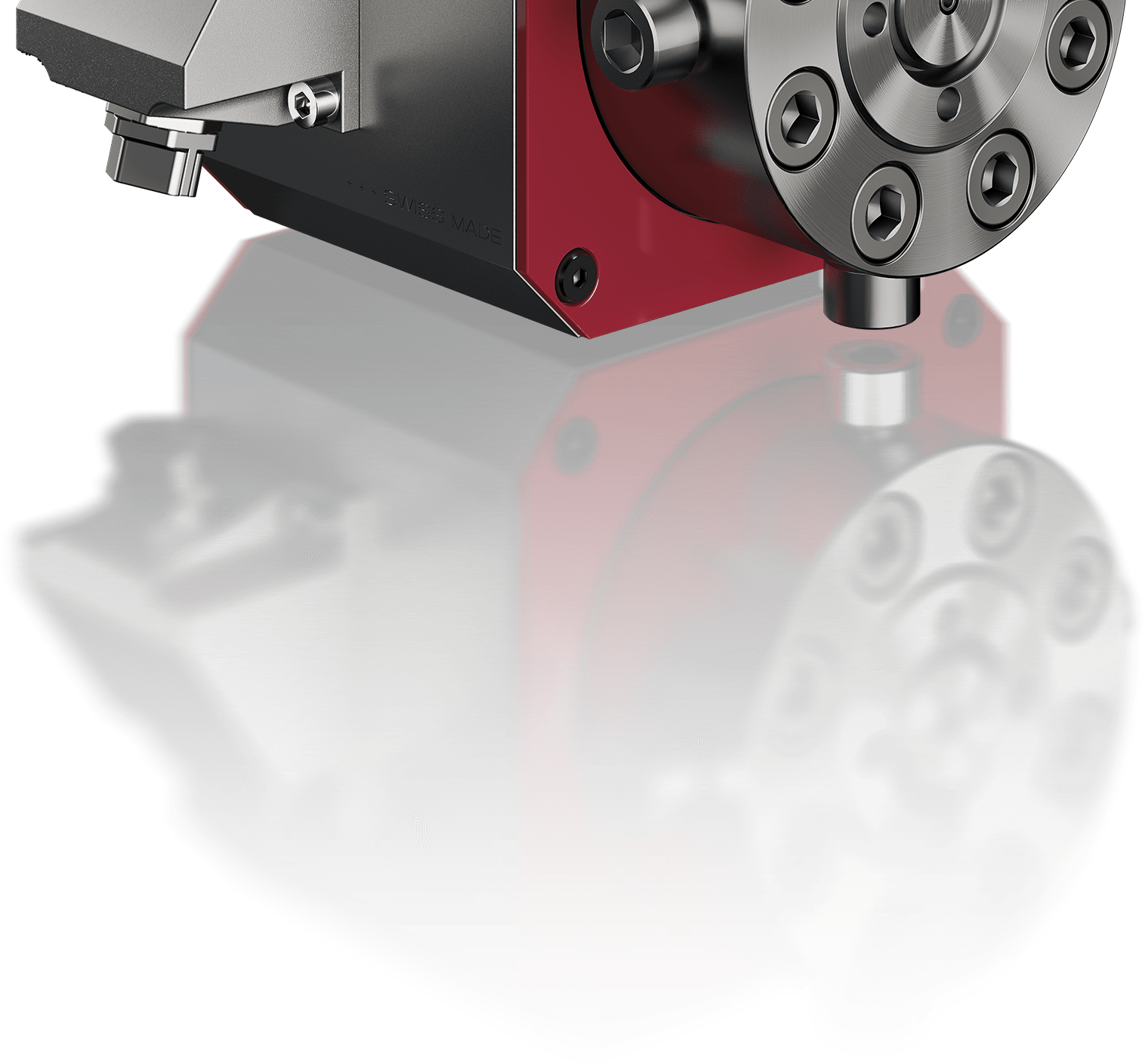

MFLEX |

MICROFLEX SYSTEM FOR 100% CONCENTRICITY |

SL |

SINGLE LAYER |

SLS |

SINGLE LAYER + SKIN OR STRIPE(S) HIGH TEMPERATURE HEAD ASSEMBLY MANUFACTURED FROM MICRODIA’S SPECIAL FLUORO-RESISTANT ALLOY: M-ALLOY |

TL |

TRIPLE LAYER |

DISTRIBUTION |

CONICAL DISTRIBUTION CARTRIDGE |

MONO-FLOW |

EASY TO CLEAN-NO HOLES OR SLOTS-NO DEAD SPOTS CONSTANT AND SMOOTH COMPOUND FLOW NO STRESS AND NO SHEAR IN THE MELTED COMPOUND |

GUM SPACE |

AXIAL DIE ADJUSTMENT |

CONNECTIONS |

FLUORO-RESISTANT CONNECTING FLANGES FOR ANY TYPE OF EXTRUDER |

TOOLING |

FLUORO-RESISTANT ALLOY OR TUNGSTEN CARBIDE SPECIAL TOOLING FOR PHYSICAL FOAM FEP |

ACCESSORIES |

ASSEMBLY AND DISASSEMBLY CLEANING KIT |

SPARE PARTS |

PERMANENT STOCK, SHIPMENT WITHIN 24 HOURS |

SERVICES |

MICRODIA ANSWERS YOUR REQUEST WITHIN 24 HOURS TECHNICAL ASSISTANCE - ENGINEERING - COMMISSIONING |

| X1 | Microflex system |

| X2 | Gum space adjustment |

| X3 | High tensile strength steel |

| X4 | Traceability |

| X5 | Aluminum cover |

| X6 | Vacuum adaptor |

| X7 | Connection block |

| X8 | Tooling |

| X9 | Special crosshead for LAN cable |

| X10 | Integrated bypass |

| X11 | Flow adjusting screw |

| X12 | Anti rotation pin |

| X13 | Fixed centering |

| X14 | Distributor |

| X15 | Thermostatic crosshead |

| X16 | Rear adjusting gum space |

| X17 | Jelly injection system |

| X18 | X/Y adjustment system |

| X19 | Manual centering |

| X20 | Crossflow (XFL) system |

| X21 | Color change (QCC) system |

| X22 | Distributor support system |

| X23 | Crosshead support trolly |

| X24 | Stainless steel connection terminal |

Specialities —